Turbine Generator Condenser Inspection

Inspection Challenges

Tube leaks can cause condensers to come off line. It’s critical for any inspection to determine the type and location of the indications causing the tube leaks. In this particular example, the component had dual tubesheet structures at each end of the tubing with multiple expansions producing significant limitations for the bobbin probe inspection. The current technology being used was not able to detect indications resulting in leaking conditions.

Recommended Solution & Advantages:

Zetec offered a solution to identify the degradation(s) types and locations causing the leaks. Zetec recommended using a CXB4 probe coupled with the Velocity software and MIZ-200 Eddy Current instrument.

The CXB4 probe allowed an enhanced level of an Eddy Current inspection including excellent crack detection in both circumferential and axial orientation. The CXB4 probe was able to determine numerous defect morphologies including inlet end erosion, circumferential and axial cracking.

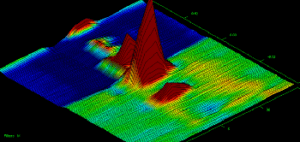

The Velocity software combined with the CXB4 probe provided two separate (axial / circumferential) cscan/waterfalls. Each display optimized the analysis process by providing the user the ability to differentiate between axial and circumferentially oriented indications. This technology is unique in the industry and delivers a simplified approach to determining the orientation of indications.

This solution provided extensive advantages including:

- Excellent detection of cracking regardless of orientation

- Provides Array and Bobbin inspection in a single pass

- Industry-leading signal to noise ratio

- Remarkable C-scan presentations

- High level of detection in a rapid inspection

Zetec Products:

Inspection Confidence in Demanding Environments

- Industry leading data Signal to Noise Ratio for superior Probability of Detection

- Rugged, cast aluminum case designed to IP-65 spec for withstanding harsh environments

- Compact & Lightweight

- A/C & battery powered

Array and Bobbin technology combined

- Ability to detect and differentiate between Axial, Circumferential and Volumetric indications

- Fast inspection speeds with accurate, detailed results

- Ridged design for improved probe life

- Excellent detection of indications at expansion transitions and support structures

Acquisition, Analysis and Data Management

- Auto Acquire

- Industry leading enhanced C-scan presentations – derived from Steam Generator software

- Tubesheet builder