NDT Solutions for Aerospace Inspections

Effective nondestructive testing (NDT) is a necessity for aircraft owners, operators and manufacturers. Aircraft inspections are normally required by law under both civilian and military regulations. The reason why is simple: to protect pilots, crew, passengers, and bystanders from malfunctioning aircraft.

Many aerospace components must be tested to ensure flight safety and regulatory compliance. This can result in a large volume of tests for companies to complete on a regular basis in order to maintain current compliance. To efficiently accomplish high-volume testing—and the recordkeeping it entails—aerospace companies rely on fast, powerful, and easy-to-use modern NDT equipment.

Zetec has been a leading manufacturer of ultrasonic and eddy current NDT equipment for decades, which are two of the most commonly used methods in aerospace NDT. Our state-of-the-art equipment can effectively complete simple or complex inspections, ensuring safety compliance while providing peace of mind.

Aerospace NDT Resources and Application Notes

To give you some examples of how our products are used to inspect aircraft components, here are several relevant resources:

- Composite Material Inspection

- Countersink Fastener Inspection

- F-15 Longeron Inspection

- Piper Aircraft Bolt Hole Inspection

- Surface and Subsurface Cracking Inspection (webinar)

- Improving Aerospace Flaw Detection (webinar)

- Friction Stir Weld Inspection (article)

- Flaw Detection Capabilities in Aerospace (white paper)

Product Recommendations for Common Aerospace NDT Applications

To help you find the right equipment for your application, we’ve listed below some of the most common aerospace NDT inspections our equipment have successfully accomplished. If you need a solution for a testing application not listed below, contact our team of experts, and we’ll help you find the equipment you need.

Click here to skip to a specific application category:

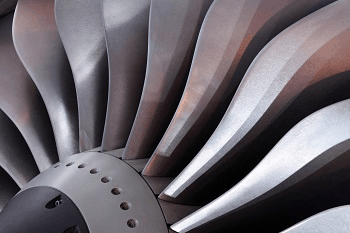

Metal Components | Metal Airframe and Fuselage | Multilayer Structures | Bolt Hole | Wheels and Landing Gear Legs | Engine / Engine Attachment / Pylon | Composite | Honeycomb

Regardless of the application, supplying NDT analysts with the best testing equipment on the market ensures the highest level of inspection accuracy and efficiency, as well as safe transportation and successful operations for years to come.

Need help finding the right equipment? Contact us today!