Gears Inspection

Inspection Challenges

Gears are a critical component in many types of industrial equipment. A gear failure can bring entire systems down which can be costly, so they must be maintained in good operating condition. Gears can be exposed to large amounts of force that can cause fatigue cracking on the surface. In order to ensure the safe operation of critical equipment and personnel safety, the importance of inspecting these gears in service is becoming increasingly prominent. There is a need for fast and reliable nondestructive evaluation (NDE) techniques for gear inspections to minimize outage time and cost but there are some key challenges. It can be difficult to inspect gears as they can be in located in a tight space with limited access. Furthermore, the complicated shapes of the gears can pose a unique inspection challenge.

Surface cracks on these gears have typically been evaluated by traditional non-destructive examinations, such as Magnetic Particle Testing (MT) and Liquid Penetrant Testing (PT). Although these types of tests may be effective at detecting surface cracks, they have their limitations. Both MT and PT require extensive surface preparation and post-inspection cleaning which can be very time consuming. Additionally, the results are highly dependent on the skills of the technician, which can lead to small defects easily being missed.

Recommended Solution

Zetec offers a solution that can reduce the inspection time, while increasing the probability of detection (POD) using a Surf-X Flexible Array Tape Probe with a MIZ-21C Handheld Eddy Current Instrument.

The eddy current array (ECA) technique is a powerful means of detecting surface and sub-surface defects. This technology has demonstrated proven reliability and is a fast, cost-effective way to carry out preventative maintenance while ensuring safety. Eddy current surface array techniques can easily replace traditional NDT methods, such as MT and PT, for surface inspection. This method provides several benefits over MT & PT, such as the capability of detecting both surface and subsurface indications, significant decreases in inspection times, and the ability to record indications providing a permanent record of the inspection.

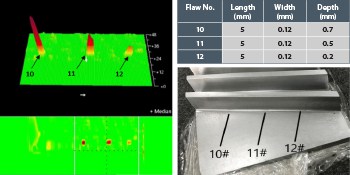

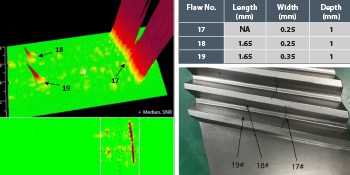

The Surf-X Flex Tape Probe is a highly flexible set of array coils. This coil set can be placed on a mold, or probe form, that is formed to the geometry of the gears, thereby providing uniform contact with the surface and minimizing liftoff variations. The result is a 2D colored display that is similar to the MT & PT qualitative results, with the added benefit of the 3D display which provides volumetric information for quantitative results.

Solution Advantages

- Ability to detect surface-breaking and sub-surface indications

- Significantly reduced inspection time and improved flaw detection

- Highly detailed quantitative results

- Full record of inspection and independent analysis of each signal

- No clean-up with no hazardous chemicals or materials requiring costly disposal

Zetec Products

MIZ-21C Eddy Current Instrument

Compact and Powerful – The Key to Successful Eddy Current Inspections

Features Include:

- Surface Array in a Handheld: Cost-effective, highly portable solution that delivers significant advantages over Liquid Penetrant Testing (PT) and Magnetic Particle Testing (MT)

- Easy to read graphical display of the inspection component makes flaws easy to detect

- Increase Uptime, Wherever You Go: Features up to a ten-hour battery life so users can operate the unit for an entire shift without recharging. Replaceable batteries support 24-hour operation

- Ergonomic Design: Small, lightweight and comfortable to handle in tight spaces. MIZ-21C minimizes arm fatigue common with other portable instruments

- Intuitive Touchscreen: Quickly rotate, zoom and pan using the two-finger capacitive display. The onscreen keyboard further increases user efficiency

- Universal Symbol Buttons & Multi-Language Software: One model for worldwide use and deployment. Universal symbol buttons handle all functions and are ideal for gloved inspections

- Built for Demanding Environments: Fully sealed and temperature rated for most outdoor conditions. Drop and vibration tested for rugged use

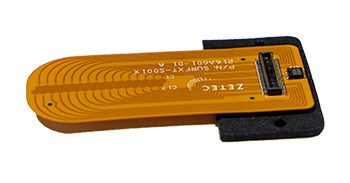

Surf-X Flexible Tape Probe

Extreme Flexibility – Designed for Complex Geometric Components

Features include:

- Highly Flexible Design: The tape probe can be attached to various probe forms or handles that conform to complex surface geometries

- Faster Inspection: Multiple coils provide for a wide area scan in a single pass compared to single coil probes

- Interchangeable Multi-Coil Probe Sets: Users in the field can change a coil set in less than a minute enabling the probe to easily adapt to different materials and surface geometries at the inspection site

- Intelligent Design: Embedded ID chip aids in proper probe configuration