How 2D Encoded Scanners and ‘Air-Born’ UT Can Simplify Pipeline NDE

By Dominic Giguère, Zetec Product Manager – UT Portable Solutions

Improvements in nondestructive testing technology and especially the software and processing power of off-the-shelf, portable phased array ultrasonic instruments mean that internal pipeline corrosion, while obviously serious, doesn’t have to be the hidden threat that it was even just a few years ago.

These highly capable phased-array UT instruments have given rise to two other emerging technologies for pipeline inspections: manual 2D encoded scanners, and a new non-mechanized encoding system that uses air-born ultrasound for tracking probe position and orientation.

Manual 2D Encoded Scanners

The latest manual 2D encoded scanners are versatile and can work on both flat and curved surfaces. Unlike wheel probes, both axes are encoded so there’s no need to draw an index line on the specimen when scanning. Their compact, lightweight, and ergonomic designs make 2D encoded scanners agile and easy to deploy even in hard-to-reach areas.

The first such scanner to hit the market is Zetec’s NDT PaintBrush, introduced in 2016.

Developed specifically for detecting wall-thickness reductions due to corrosion, abrasion, or erosion, NDT Paintbrush is designed to work with the company’s TOPAZ line of portable phased array UT instruments. Two side-by-side encoded wheels track the position of the scanner in real time and allow the operator to monitor the coverage area on the TOPAZ display as he or she moves the probe over the surface of the material.

If there’s coverage overlap, the instrument’s software will take into account the minimum thickness at the same position; if a portion of the test area has not been scanned, a real-time image will be displayed on the scanner.

NDT Paintbrush’s 2D encoding, data visualization, and tactile feedback—like brushing on a coat of paint—make corrosion inspections more intuitive and reliable.

‘Air-born’ UT Encoding

For suppliers of UT equipment and corrosion probes, it’s been a longstanding goal to combine the simplicity and cost effectiveness of manual inspections with the rigor and data quality of mechanized position and orientation encoding systems and automated ultrasonic testing (AUT).

In 2018, Structural Integrity Associates introduced LATITUDE, a non-mechanized position and orientation encoding system that enables an operator to collect high-quality encoded data using a manual examination process. The manually applied sensor allows the examiner to more efficiently discern and characterize component damage, and provides tactile feedback on surface conditions, contact, and coupling that improves signal-to-noise results compared to mechanized delivery.

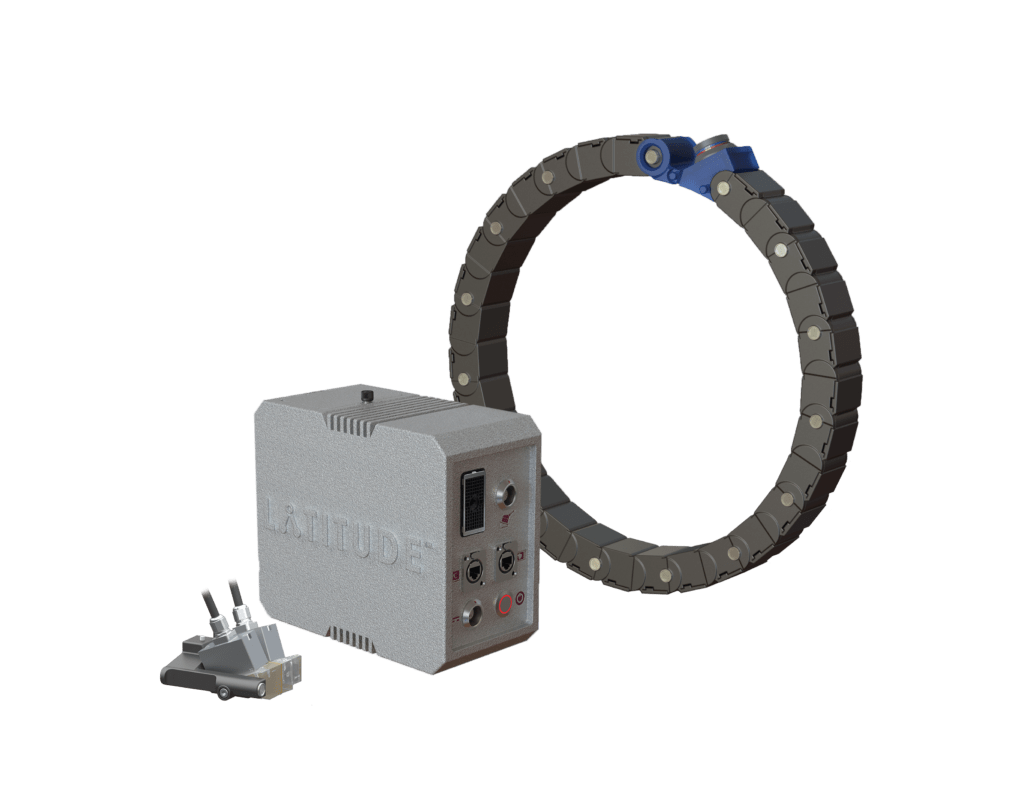

The LATITUDE encoding system consists of three components:

- A transmitter contains multiple sensors for determining the axial position, circumferential position, and skew (rotation) of the fixture. It is typically affixed to an NDE sensor that is being used to conduct an examination, such as a phased array UT probe, an eddy current testing (ECT) probe, or any of several other kinds of NDE sensors.

- The LATITUDE receiver array consists of a conformable, magnetic collar for use on flat and curved surfaces. Depending on the application, the collar can be wrapped around the pipe circumference, stretched along the pipe axis, or be otherwise placed on a flat or curving surface.

- An electronic control unit (ECU) for collecting “air-born” ultrasonic signals, translating them into position information, and communicating with the NDE data acquisition system. LATITUDE’s ECU is integrated with Zetec’s TOPAZ instrument, which streamlines the setup, calibration, and control of the system. The ECU is powered by two hot-swappable batteries that provide up to seven hours of use.

LATITUDE encoding technology can be applied to a variety of NDE sensor types including phased array, TOFD, array eddy current, and others that warrant or require a permanent data record. When it’s combined with inspection procedures such as scanning involving a detection-only approach, personnel and inspection time is significantly reduced compared to what a typical automated UT procedure would require. The result is increased efficiency and improved overall production.

For corrosion mapping, LATITUDE enables the encoding of high-resolution thickness data while manually manipulating the probe, resulting in a composite thickness map that requires little to no post-processing for analysis.

Furthermore, the data files created using this approach can be imported into finite-element analysis (FEA) software to perform engineering analyses of the component with wall loss.

A successful corrosion mapping inspection is the result of the combination of a high probability of detection and the confidence that the full area of interest has been totally covered. The broader availability of two-axis scanners has helped the gain in confidence in the surface coverage.

However, the lack of agility and extra time and cost required to deploy them has opened the door to innovative, agile new 2D encoded scanners like NDT PaintBrush, which can determine at any instant the probe position and the scanner’s orientation, and LATITUDE, which can ensure the collection of high-quality encoded data without a mechanical rack or carrier.

While fully automated UT offers several advantages for critical inspections, the ability to freely move a probe by hand while tracking probe position and orientation combines the best of both worlds—detailed records, a tactile feedback, and immediate visualization without extra cost or complexity.

Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. To learn more, contact Zetec today!