Composite Material Inspection

Inspection Challenges

Inspections of composite materials, most commonly conducted in the aerospace industry, provide numerous key challenges. The very thin material makes near surface resolution critical, yet at times difficult to accurately complete. In addition, composite material is not suitable for using magnetic-type scanners and these types of inspections are traditionally performed in immersion, which is not always possible for large-sized parts.

Recommended Solution

A recommended solution involves phased array ultrasound testing (PAUT) with a portable scanner and flexible immersion probe that doesn’t require the need for an immersion tank. The solution can effectively and efficiently inspect carbon fiber reinforced polymer (CFRP) surfaces, offer improved near surface resolution all with the confidence of constant tracking and complete coverage.

The proposed solution includes the following components and techniques:

A powerful and portable PAUT unit with all tools and features to efficiently set up and deploy the following recommended examination techniques

Free orientation scanner that provides tracking and optimal wheels for non-magnetic surfaces

Flexible wedge and local immersion probe that can provide scanning without the need for an immersion tank

Zetec Products

Zetec offers the optimal solution for this type of inspection challenge, delivering a highly reliable and efficient composite inspection. The following complete solution kit from Zetec features the necessary components and tools to confidently perform all the examination techniques in the inspection.

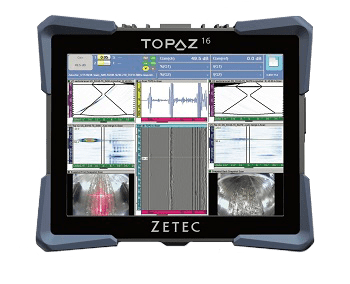

TOPAZ16 fully integrated, portable PAUT unit

TOPAZ16 is a 16 channel fully integrated PAUT device. Featuring best in class software capabilities, multi-touch screen and proven Zetec quality, TOPAZ16 delivers unmatched value. It is sized for convenience and built to perform. Features include:

- One instrument for everything: from preparation to reporting, TOPAZ16 is the complete solution. With easy setup and onboard analysis, reduce the amount of equipment needed to perform an inspection. Available in 16/64 or 16/128 configurations, TOPAZ16 is adaptable for meeting your specific inspection needs.

- Highly capable: fast imaging using online S-Scan and C-Scan

- Industrially proven: driven by UtraVision Touch on-board software ensuring an efficient inspection workflow

- Highly responsive: multi-touch screen that not only offers the best resolution in its class but also one of the largest display size to instrument footprint ratios

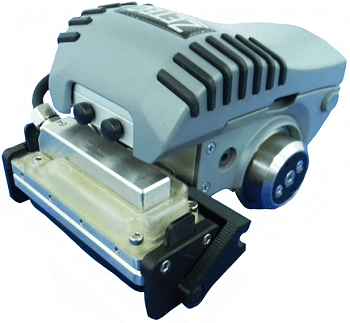

NDT PaintBrush is an extremely agile scanner that can operate on both flat and curved surfaces, providing the confidence of 100% area coverage and optimal probability of detection. Features include:

- Location and orientation tracking so you’ll never miss an area

- Dedicated knurled wheels to optimize tracking on non-magnetic materials like CFRP

Immersion Probe. Features include:

- Bladder allows for coupling without water tank

- 1 mm pitch for extended coverage

- Membrane with impedance optimized for composite materials for maximum near-surface resolution

- Outlet to facilitate filling process and air bubble removal

Benefits

Adaptable and Responsive

- Flexible membrane allows adequate coupling without immersion tank

- Composite impedance matching allows improved near-surface resolution

Confident and Complete

- Highly portable solution with full inspection capabilities

- Constant tracking and complete coverage, every time

Highly Intuitive

- Easy setup and deployment

- Specifically designed for CFRP inspections