Using the Total Focusing Method Algorithm to Enhance PAUT Imaging

Companies depend on phased array ultrasonic testing (PAUT) to inspect their assets and equipment for signs of deterioration and damage. PAUT uses acoustic waves to measure the interiors of solid objects, including metals and composites. Fast, effective, and dependable, PAUT improves on conventional ultrasonic methods by using an array of transmitters and receivers. This allows technicians to scan objects more rapidly by covering more area at once using multiple, separate beams.

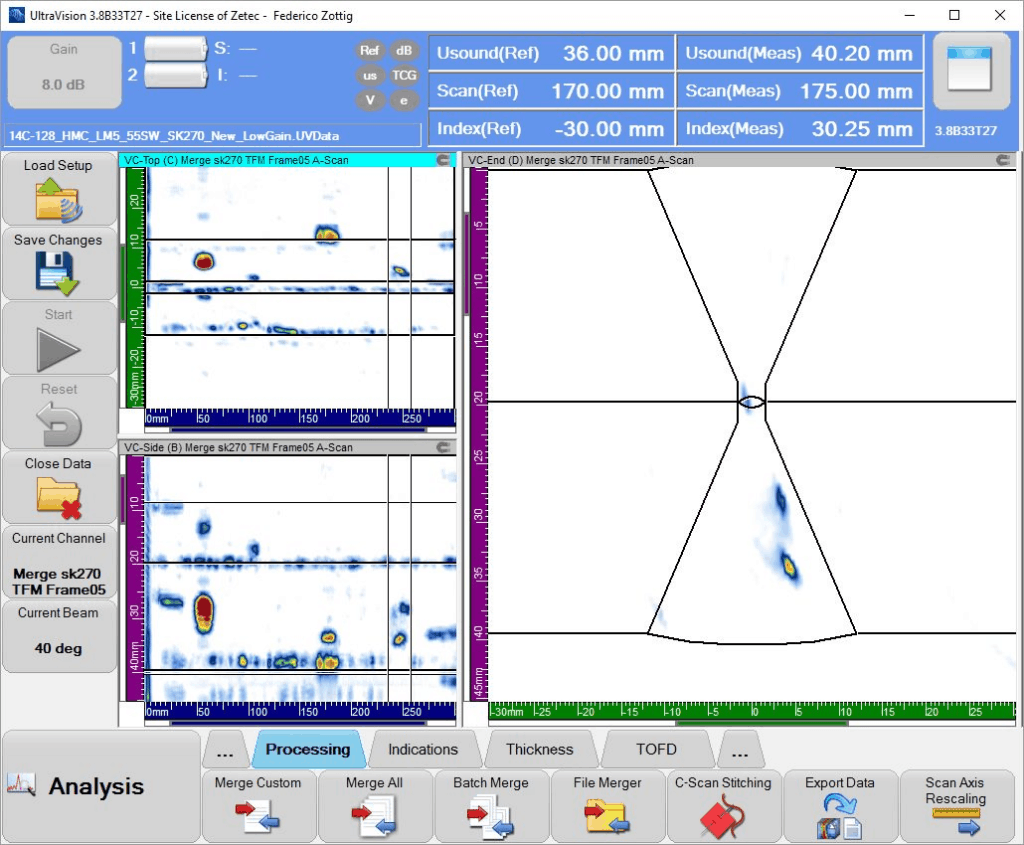

To display scan images, PAUT software summarizes the results of each independent beam. While this provides a useful composite picture, some individual detail is lost upon summary. For even greater clarity—needed for challenging applications—analysis of the raw A-scan data from every transmitter-receiver pair might be necessary. To safeguard critical assets, companies invest in PAUT equipment capable of using the total focusing method (TFM) algorithm.

What Is the Total Focusing Method Algorithm?

The total focusing method algorithm can provide greater clarity and precision compared to standard phased array ultrasonic testing. To understand how, it’s important to grasp what information is lost during standard phased array.

Standard phased array technology employs a “sector scan” method of inspection. First, the software decides on a focal law—the calculation used to interpret scan results. Then, the array pulses, receives a signal back, and digitizes the signal. It uses the delay law to sum the signals from each receiver together, discarding raw data.

Then, the instrument changes beam angles, calculates a new focal law, and pulses again to repeat this process. The results of each sector scan, are summarized to create a Sectorial, Linear, or Compound scan image.

In contrast, the total focusing method algorithm does not summarize. Data from each transmitter/receiver in the array is separately digitized and saved, a technique known as Full Matrix Capture (FMC). From this data, the software calculates a focal law for every pixel in the image. Analyzing FMC data using TFM focal laws provides a different view from conventional phased array.

TFM does not replace standard phased array. It is, however, a powerful tool to augment PAUT, improving image resolution and the ability to characterize smaller flaws.

Uses for TFM in Phased Array Ultrasound

Utilizing the total focusing method can help technicians identify small defects or flaws in challenging inspections. While standard PAUT remains the method of code and regulation, TFM can still help companies improve safety and maintenance results. Here are some examples of useful applications, based on case studies, for TFM:

Issue |

Industries |

Need |

| Hydrogen Induced Cracking | Wet H2S refinery environments | This type of cracking can occur at low temperatures. Standard PAUT may not show stepwise internal cracks between hydrogen blisters. |

| High Temperature Hydrogen Attack | Refineries, Petrochemical, Chemical | Voids in steel < 0.1mm in the early stages of HTHA are difficult to detect without the advanced capabilities of TFM. |

| Dissimilar Metal Welds | Nuclear, Oil and Gas | Complex geometries, multiple acoustic interfaces, and austenitic structure propagation issues create difficulty for standard PAUT. |

Identifying issues early on using TFM allows managers to plan repairs or replacements well in advance, ensuring the most efficient allocation of maintenance resources. Swapping unplanned downtime for scheduled maintenance keeps operations moving, and detecting failure points early protects workers as well as the bottom line.

Not all ultrasonic testing equipment supports TFM. But the top-shelf equipment that does provides powerful, efficient ultrasonic scanning in its own right, as well as the added benefits of the advanced TFM algorithm.

Selecting Total Focusing Method Hardware

Ultrasonic testing equipment that supports full matrix capture (FMC) and the total focusing method algorithm typically features more power than basic PAUT instruments. More advanced equipment features 64 active channels and up to 1 million data points per frame. This advanced focusing can improve the resolution of flaw images and inspection coverage. It goes above and beyond standard PAUT code compliance, and enables highly detailed recordkeeping by saving raw data for complete flaw characterization.

Often used in demanding environments, ultrasonic testing equipment should be highly durable. Equipment built without air intakes will last longer in particle-rich areas. Lightweight, portable equipment improves inspection flexibility outdoors and on the refinery floor. Powerful equipment is only effective if it can withstand the conditions it works in.

TFM is one of many important tools in the hands of NDT inspectors. It can enhance PAUT effectiveness. Equipment capable of supporting TFM can help streamline facility inspection programs for applications demanding this type of advanced imaging capabilities. Choosing ultrasonic testing equipment with TFM rewards companies with code compliance, safer facilities, and smooth operations.

Zetec provides leading ultrasonic equipment that supports TFM. The TOPAZ64 UT instrument offers several features unrivaled in its class. To learn more, contact Zetec today.