"Uncontrolled variation is the enemy of quality." That quote, coined by renowned quality management expert Dr. W. Edwards Deming, can

Read More

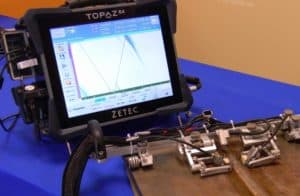

Phased array ultrasonic testing (PAUT) is an excellent method for inspecting a wide range of components. It's more in-depth than

Read More

The design and inspection of helicopters—whether military, commercial, or civilian—are subject to strict regulations. This makes sense: helicopters are a

Read More

Being able to detect a flaw when it's still tiny can save companies thousands—or even millions—of dollars worth of repairs.

Read More

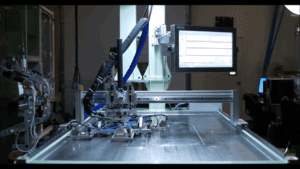

The rail industry is always looking for better, faster, safer, and more efficient means of rail flaw detection. And more

Read More

Nondestructive testing of austenitic steels can prove challenging because of dead zones. These coarse metals create issues with standard ultrasonic

Read More

The processing, storage, and transportation of oil and gas is an industry segment fraught with risks. A small leak can

Read More

Eddy current testing for aircraft is a tried and true method of ensuring the efficacy of metal components. While it

Read More

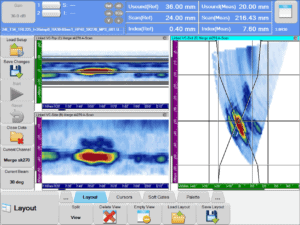

There's a saying about non-destructive testing: if the flaws were large, you wouldn't need equipment to see it. Ultrasonic testing

Read More

One only needs to look at the size of flaws NDT testing can locate to see why ultrasonic testing calibration

Read More