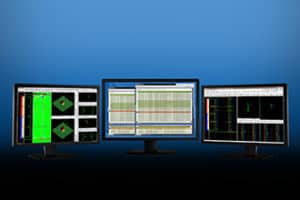

Powerful, automated eddy current analysis software allows inspections to be completed with greater efficiency, accuracy, and consistency.

Read More

The cost of investing in proper equipment, training, and time for ultrasonic thickness measurement is grossly overbalanced by the prevention

Read More

The two most important methods for aircraft nondestructive testing include eddy current testing (ECT) and ultrasonic testing (UT).

Read More

Various nondestructive testing techniques can detect cracks and other flaws, but when it comes to railway track inspection technology, the

Read More

New technologies incarnate in more efficient pipeline weld inspection solutions can increase oil and gas profits by decreasing pipeline inspection

Read More

Eddy current testing is an efficient, cost-effective means to ensure the quality of materials and components used in the manufacturing

Read More

When testing steel structures, nondestructive testing (NDT) inspectors need instruments that permit flexible scanning and deeper probing.

Read More

It’s not about comparing time-of-flight diffraction vs phased array—it’s about combining them.

Read More

The right NDT companies can successfully combine ECT and 10 CFR part 21 standards to foster workplace safety and streamline

Read More

Advances in ultrasonic technology are replacing standard UT methods and improving the quality and efficiency of composite inspection techniques.

Read More