The Importance of Pressure Vessel Nozzle NDT

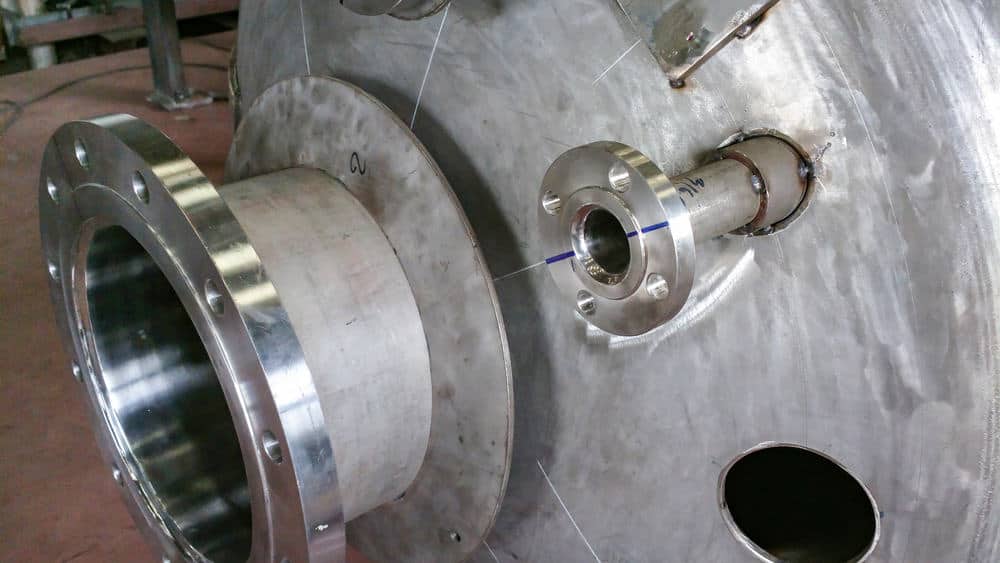

In power generation, oil and gas, and other industries, pressure vessels have been one of the major infrastructural components. Pressure nozzles are heavy-duty additions that facilitate the inflow and outflow of these fluids from the pressure vessel for further processing. Adding the nozzle to the vessel requires creating an opening on the vessel and joining the nozzle to it. Structurally, this process interrupts the shell of the vessel causing discontinuities in the vessel wall. Industries must ensure that the strength of the pressure vessel is not affected by any errors that may occur during the nozzle weld. Non-destructive testing (NDT) with ultrasonic scanning is a trusted inspection method to analyze the quality of welds holding the pressure vessel nozzle.

Potential Flaws in Pressure Vessel Nozzle Welding

Pressure vessels are exposed to extreme temperatures and pressures, and in some cases, steam or water hammering. So, maintaining the structural soundness of the vessel is critical for production and industrial safety.

A pressure vessel may consist of a large number of nozzles. These nozzles are generally secured to the vessel with the help of welds in the inside as well as the outside diameter of the vessel wall. Thus, they are also the weakest and critical part considering the stress diverted towards it due to the tampering of the shell of the vessel wall. For structural integrity, they must have a strength profile that matches or exceeds that of the pressure vessel itself. However, there are challenges that nozzle welds can cause, such as:

- Cracking due to thermal fatigue, external load, or lack of penetration. External load can occur due to poor design and estimation of nozzle load, leading to cracks along the contour of the weld.

- Stress corrosion as well as discontinuities such as porosity and inclusions due to inaccurate weld parameters.

The sooner these flaws are detected, the more beneficial it is for industries to optimize their weld process to ensure safety. Safety can be a major public health concern, especially for industries that perform petroleum or nuclear handling.

Simply conducting a visual inspection is not always effective in identifying potential flaws in nozzle welds. Instead, ultrasonic non-destructive testing is an ideal method for ensuring that the weld is safe enough to hold the nozzle in place without having to compromise on the service life of the pressure vessel and jeopardizing production safety.

Ultrasonic Scanning for Error Detection

One of the main obstacles in the inspection of nozzle welds is the varying geometry of the vessel and the nozzle. When inspecting the “saddle”, geometry requires the probe to be able to conform to the axial and circumferential changes. Advanced ultrasonic testing scanning solutions provide flexibility that allows complete coverage of the weld along with its complex geometries.

Specific UT solutions are able to identify welding flaws through thickness- and corrosion-mapping, and weld inspection. Specifically, phased array ultrasonic testing (PAUT) technology allows technicians to utilize multiple transducers and analyze the reflected ultrasonic signals to check for any irregularities in the inspection area. These advanced scanning solutions which include versatile instrumentation, 3D visualization software tools, 2-D matrix array probes, and a scanner provide the following advantages during nozzle weld inspection:

- Flexibility to inspect along curves and offsets

- Reliable material thickness inspection and identification of irregularities

- More coverage in a short span of time

- High-resolution and detailed 3D mapping of the scanned surface

Assessing Nozzle Weld with NDT

Ultrasonic NDT technology provides an ideal solution for ensuring the quality of nozzle welds in maintaining the integrity of a pressure vessel. Advanced technology provides technicians with the advantage of designing and validating the inspection technique. And, equipment flexibility allows for complete coverage with its ability to conformance to changing curvatures. The ability to identify flaws through high-resolution imaging and execute the inspection for complex geometries allows industries to ensure the safety of the pressure vessel nozzle.

Zetec is a leading provider of high-performance NDT solutions for nozzle weld inspection using advanced ultrasonic inspection technologies. Our advanced NDT instruments, software, scanners, and probes offer flexibility and precision in ensuring the weld quality of the pressure vessel nozzle. Contact us today to learn more about our NDT solutions.