Nondestructive Testing Overview: A Comprehensive Guide to NDT

Introduction to Nondestructive Testing

We live in a constructed world, surrounded by large structures, dependent on complex machines. Our lives and livelihoods are inextricably linked to the proper function of our infrastructure and machinery. For this to be safely possible, we must have absolute confidence in the technologies we rely on. Nondestructive testing provides that confidence.

In many industries around the world, nondestructive testing is required by law. Where it is not, it remains a compelling and convincing best practice. Mastering this complex subject takes decades, and is the province of those who dedicate their lives to this profession. It demands significant training and practical experience across a wide range of scenarios. Even after 30 years of testing, it’s still possible to see something entirely new.

However, absent decades of experience, company or government managers must often still make decisions regarding their nondestructive testing programs. To make smart choices, it’s important to have a sound understanding of the purpose, applications, requirements, and different methods of nondestructive testing. This overview is intended to serve as a guide to the subject, providing foundational information on each aspect of nondestructive testing, including:

- The Definition of Nondestructive Testing

- The Purpose of NDT

- Industries Using NDT

- Requirements for NDT

- Training and Certification

- Types of NDT

- Comparing NDT Methods

- Choosing the Right NDT Method for Your Application

Definition of Nondestructive Testing

First, what exactly is nondestructive testing? Nondestructive testing (NDT), as it is commonly understood, refers to any means of determining the strength and integrity of an object without destroying the object. Other labels, such as nondestructive inspection (NDI), nondestructive evaluation (NDE), and nondestructive examination (NDE), are used interchangeably. Different labels are used more commonly in different geographical areas, or by different manufacturers.

Whichever label is used, NDT describes a category of examination, not a specific testing method. Some of the most common types of nondestructive testing include ultrasonic testing, eddy current testing, liquid penetrant testing, magnetic particle testing, radiography, laser testing, and visual inspection.

Each label refers to the means of testing—ultrasonic testing harnesses high-frequency sound waves, for example. There are several more types of nondestructive testing, which will be examined later in this overview. With the exception of visual testing (a broad term, used to describe all manner of inspections using the primary senses: visual, auditory, tactile, and olfactory), each testing method requires a dedicated apparatus, designed for the purpose. Understanding the strengths and weaknesses of each method helps companies meet their testing needs in the most efficient way possible. Technology made the modern world; nondestructive testing makes it safe to use.

Purpose of Nondestructive Testing

The basic purpose of nondestructive testing is to assess the qualities of an object without destroying it. The underlying reason for doing that is risk management. While nondestructive testing does not eliminate risk, it can significantly reduce or mitigate it.

Nondestructive testing contrasts and combines with destructive testing. NDT allows objects and equipment actually in service to be tested. Conversely, after an object has been tested destructively, it cannot be returned to service. So, the purpose of NDT compared to destructive testing is to mitigate the risk of damage to important equipment or infrastructure in the field.

The two serve intertwining purposes. Destructive testing provides an exact estimate of what it takes to destroy an object. Knowing the limits set by destructive testing in a laboratory, technicians perform nondestructive testing in the field to ascertain how close an object is to reaching those limits. If an object is too close to the limit, NDT allows it to be safely repaired or replaced before any harm is done.

Should all objects be tested? No. Nondestructive testing is worthwhile when the risk of an object failing outweighs the cost of testing it. High-risk objects are those that endanger the lives of those around them upon failure, such as passenger jets or nuclear reactors. High-risk objects also include those which can cause severe financial or environmental harm, such as oil pipelines. The cost of testing is a function of equipment cost and employee time; employee time includes both training and actual testing.

Fortunately, companies don’t have to guess which equipment or infrastructure to test—many nondestructive testing requirements are dictated by national governments. Governments often base their legal requirements on information published by international standards bodies, such as ASTM or ISO. Thus, a derived—though nonetheless essential—purpose of NDT is ensuring regulatory compliance. Flaunting NDT requirements can quickly become more expensive in fines and penalties than simply following them.

Industries Using Nondestructive Testing

Nondestructive testing is widely used across many important global industries. Any industry with large physical equipment or infrastructure is likely to use some kind of nondestructive testing. Additionally, within each industry, several methods of NDT are commonly practiced. For example, airlines will use ultrasonic testing to examine turbine fan blades and eddy current testing to search for surface or subsurface flaws in multilayer structures.

Industries that commonly practice nondestructive testing include:

Aviation

Aerospace manufacturers, airlines, and repair services are all required by law to perform a variety of periodic NDT inspections. Nearly every aspect of an airplane or helicopter must be inspected at a specified interval. Spacecraft and drones must be inspected as well. Many different NDT techniques are used in aviation and aerospace, including ultrasonic, eddy current, and others.

Automotive

While vehicle owners are not required to perform NDT, manufacturers are. To prevent material failure on the road, manufacturers must inspect vehicle components for cracks and flaws, issues arising from improper heat treatment, and unacceptable material mixes.

Rail

Both trains and their tracks require NDT, as does much related intermodal storage and logistics hardware. Train car wheels, axles, brakes, and hydraulic systems must be inspected, as well as the rails and their frogs. Cranes, risers, and holding tanks require periodic safety inspections, particularly holding tanks storing hazardous materials.

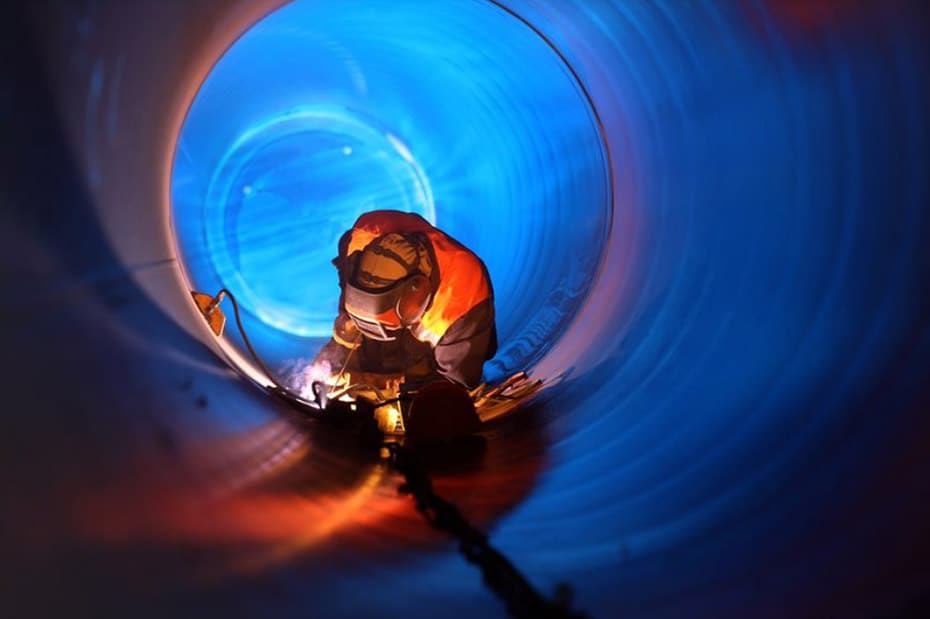

Oil and Gas

Responsible for thousands of miles and trillions of dollars of infrastructure and equipment, all divisions of the oil and gas industry rely on NDT to prevent accidents and secure their investments. Drill sites, pipelines, and refineries employ NDT teams to constantly perform inspections of welds, pipes, risers, tanks, and large forgings. The sheer volume of the inspections performed by the oil and gas industry rewards efficient, portable NDT equipment.

Power Generation

Large power plants have zero tolerance for failure and stringent testing requirements. Nuclear plants, in particular, trust their NDT solutions to ensure safe operation. But coal, oil, and gas plants all depend on NDT to detect flaws in their turbines, tubing, and related systems. Renewable power plants including hydropower and wind test their hardware and systems integrity as well.

Manufacturing

Heavy manufacturing companies typically use NDT to ensure product quality prior to delivery. Pipe, steel, and tubing manufacturers inspect for material and weld integrity. Manufacturers of turbines, large vessels, and ships likewise trust NDT to determine whether their products meet appropriate specifications. Specialty composite manufacturers can detect voids, delamination, density variations, porosity, stress, damage, and foreign materials present in their products. NDT in manufacturing not only guarantees product safety, but also a company’s reputation.

Marine

Large and small marine craft depend on NDT to prevent materials failure at sea. Metal and composite hulls are inspected by their manufacturers, and periodically while in service. Propeller blades, turbines, and internal equipment such as holding tanks or boilers must be routinely inspected as well. Nuclear powered ships must test their systems as carefully as with steam generator plants found on land. Due to the difficulties of maritime law, marine NDT regimes are often primarily the purview of ship owners and manufacturers, though informed by international standards.

Military

Militaries rely on aerospace, naval, and nuclear technologies, and must diligently inspect the equipment in their charge to ensure mission reliability. Military vehicles, munitions, and installations also commonly require NDT inspections.

Utilities

Both power and water utilities use NDT to make certain their infrastructure remains safe and effective. Wastewater plants, for example, inspect for tank, pond, and pipe integrity.

Regardless of industry, the most common uses of NDT are to test the integrity of structural materials. These materials include metals of varying compositions and thicknesses, composite materials, fibers, and plastics. The need for NDT for a given application is derived from the likelihood and consequences of the application’s failure.

Requirements for Nondestructive Testing

Certain minimum standards for nondestructive testing are prescribed by law. Different nations or bodies follow different standards, so companies operating in multiple countries may have to meet different testing or reporting requirements for the same application. Companies subject to overlapping restrictions must follow the most stringent of them.

Airlines, oil and gas companies, and manufacturers have the most exposure to complex and overlapping regulatory requirements. NDT programs should be developed in consultation with appropriate experts or specialist legal counsel to ensure full compliance.

Most governmental standards for NDT are based on the recommendations of independent international organizations, including ISO and ASTM. These organizations base their standards in part on the research of manufacturers and several national and international trade associations. These trade associations include the International Committee for Non-Destructive Testing, the American Society for Nondestructive Testing, and the Nondestructive Testing Management Association.

Nondestructive testing regulations can specify parts to be tested, methods to be used, periodicity of testing, minimum acceptability values, and recordkeeping standards. NDT manufacturers use these standards as references when developing inspection equipment and solutions. Standards and equipment evolve together, with more effective solutions rising to meet more stringent requirements as they emerge. Manufacturers should be able to demonstrate how their products meet regulatory requirements for any application they market.

Training and Certification for Nondestructive Testing

The successful operation of nondestructive testing technology requires adequate training and experience. In certain cases, when certification of NDT personnel is required by standards, codes or regulations, many certify their personnel in accordance with the international standard ISO 9712. However, as NDT falls under the purview of different regulatory regimes, so does certification and training. While there is no one central, ultimate NDT training authority, training options remain nevertheless available. Training courses are provided by product manufacturers, third-party organizations, and employers themselves. Employers enjoy final discretion in setting requirements for employee NDT training.

NDT training is typically divided into three levels, roughly corresponding to apprentice, journeyman, and master-level understanding. In the industry, these are known as Level I, Level II, and Level III certifications.

At the most basic level, NDT technicians should demonstrate proficiency in one or more limited evaluation types, i.e., ultrasonic crack detection in welds. They should be able to determine whether an application passes or fails evaluation, and document the results. Technicians should also be able to set up, calibrate, store, and observe safety measures for one or more types of NDT equipment. Level 1 technicians should be supervised by technicians of a higher level.

Intermediate NDT technicians should demonstrate an advanced understanding of the abilities and weaknesses of their NDT methods. They should be familiar with the relationship between test standards and methods as well as internal and external codes and regulations. Level II technicians can set up and calibrate equipment as well as interpret results. They can supervise a team of Level I technicians and compile reports for presentation.

Expert NDT technicians develop the NDT strategies which Level I and II technicians implement. They convert external regulations into internal best practices. They designate test methods and standards and can be responsible for choosing or recommending equipment. In the absence of prescribed standards, Level III technicians should have the means to develop standards of their own. Level III technicians supervise and examine Level I and II technicians.

Successful NDT evaluations require both theoretical and applied knowledge. Experience, also, is an irreplaceable teacher. As part of their certification requirements, NDT technicians should prove proficiency in written and practical examinations, while minimum experience requirements ensure that important inspections are in proven hands.

Types of Nondestructive Testing

Many different types of NDT have developed over centuries, from the simplest visual and leak tests to advanced ultrasonic or radiography. Each different material to be tested has different properties, some of which are more conducive to one type of NDT than another. NDT methods differ based on their means of testing, the equipment required, the speed and coverage they provide, and, in some cases, the safety precautions necessary.

There is no one all-around “best” NDT method. The best method in any scenario is the one that most closely meets the needs of the organization using it. In modern industry, speed, ease of use, and application range are often preferred qualities in NDT solutions.

Click here to skip to a specific NDT method:

Ultrasonic Testing | Eddy Current Testing | Visual Testing | Long-Range Ultrasonic Testing | Magnetic Flux Leakage | Laser Testing | Radiographic Testing | Magnetic Particle Testing | Acoustic Emission Testing | Thermal/Infrared Testing | Vibration Analysis | Liquid Penetrant Testing | Leak Testing

Ultrasonic Testing (UT)

Ultrasonic testing has proven itself to be one of the most effective methods of modern NDT. This method works by inducing high-frequency sound waves into solid objects, typically metal or composites. The travel of the sound waves is affected by irregularities such as density variations, cracks, voids, honeycombs, or foreign objects. By collecting and interpreting returned sound waves, ultrasonic testing equipment can map the interior of many solid objects. Depending on the equipment used and the requirements of the application, waves can be collected as they reflect back or pass through the material being scanned.

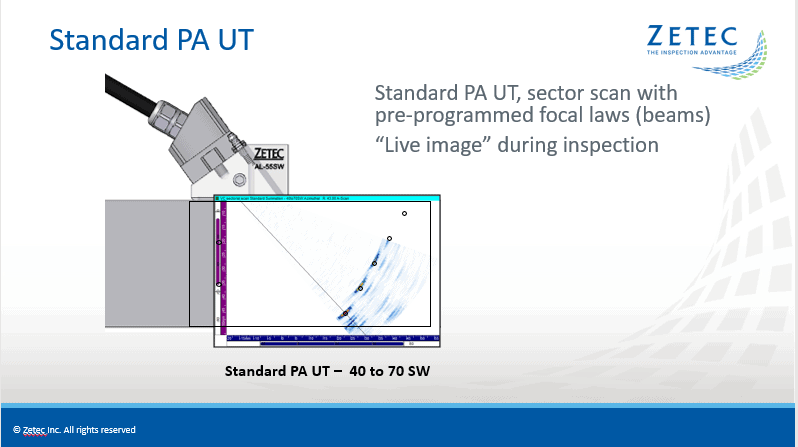

Ultrasonic testing relies on transducers to convert electrical energy into ultrasonic waves. While older methods used a single transducer at a time, modern phased array ultrasonic testing (PAUT) equipment uses several transducers operating in tandem. This technique greatly increases inspection speed, coverage area, and specificity.

Recently, advanced PAUT instruments have added higher performance capabilities including time of flight diffraction (TOFD) and the total focusing method (TFM). These newer techniques are ideal for handling more complex inspections.

The use of ultrasonic equipment is ubiquitous for volumetric testing across industries, due to its several advantages. PAUT provides fast, accurate readings, with little setup required. The equipment itself can be light and portable for field operations and yet strong enough to handle adverse environments. The range of testing applications ultrasonic covers makes the technology attractive to large organizations, as it simplifies company equipment procurement and training regimens.

Like all NDT methods, ultrasonic testing is not perfect for every application. Materials with coarser grains, like iron, interfere with wave transmission. Odd geometries, including curved surfaces, can sometimes create coverage difficulties without a defined advanced technique or complete solution. Additionally, probe quality significantly affects penetration depth and image quality.

Read more about advanced ultrasonic testing equipment and software

Eddy Current Testing (ECT)

Eddy current testing uses magnetic fields to form images of conductive materials. Changes in material properties create discontinuities in the field, similar to how rocks create eddies in streams. These changes provide indications of corrosion, cracks, voids, honeycombing, delamination, and thickness loss.

Eddy current technology finds regular use in industry due to its portability, speed, and accuracy. One of the most critical uses for eddy current testing is the power generation industry. Eddy current technology has proven effective and economical for inspecting heat exchanger and chiller tubes. Handheld eddy current equipment allows for inspections in situ, reducing the amount of downtime required to perform inspections.

A recent innovation in eddy current testing is eddy current array (ECA) technology, ideal for surface and near-surface mapping across a range of industries including aerospace, rail, manufacturing, oil and gas. ECA is an extremely fast, cost-effective and easy to use technique that provides highly accurate results.

While eddy current technology can penetrate thin nonconductive coatings, like the zinc on galvanized steel, its use is otherwise limited to conductive materials. Additionally, eddy current can have difficulty with complex geometries or large areas. While these limit the range of eddy current equipment, it remains a highly effective tool within its parameters.

Read more about eddy current nondestructive testing solutions

Visual Testing (VT)

The oldest type of nondestructive testing is visual testing. It uses low-power equipment including borescopes and fiberscopes for monitoring imperfections. Fast, inexpensive, and direct, visual testing can be an initial tool to identify asset and infrastructure issues from cracks to corrosion. However, visual testing is inadequate when attempting to identify many different types of material failure early enough to safely repair or replace equipment. When vision is obscured, or defects are small or internal, visual inspection fails. In fact, the various shortcomings of visual inspection created the necessity for every other form of NDT.

Long-Range Ultrasonic Testing (LRUT)

Long-range UT is an ultrasonic testing method used specifically for piping. Ultrasonic transducers or coils are built into a ring, which travels along the pipe. The transducers emit waves, which provide an image of the pipe wall’s interior. Irregularities and changes in thickness alter the waves, revealing themselves to technicians. This method does not require a liquid couplant between transducers and the surface.

Magnetic Flux Leakage (MFL)

Magnetic flux leakage is an effective field testing technique primarily used to inspect large pipes, tubes, and tank floors. A powerful magnet is used to saturate the material with a magnetic field. A sensor detects fluctuations in the magnetic field caused by differences in material properties, such as corrosion, pitting, thickness loss, or cracks. Pipes can be scanned without removing insulation, using a magnet and sensor which travels along the length of the cylinder. Tank floors must be scanned using field generators arranged in series. This technology is good for ferrous materials and a capable means of detecting flaws in large infrastructure.

Laser Testing Methods (LM)

Three types of laser-based NDT dominate—profilometry, shearography, and holographic testing. Profilometry uses a spinning laser to image the external surface of pipes and tubes, detecting cracks, erosion, or pitting.

Shearography is a highly accurate “before and after” method of detecting material flaws. A laser records an image of the material before and after an application of stress and uses the differences detected to inference internal structures.

Holography uses a similar “before and after” method to inference defects on the scale of micrometers. The two techniques differ in equipment and software used to generate results. Shearography is preferred for large surfaces; holography for small ones.

Radiographic Testing (RT)

Radiographic testing has entered the public imagination through x-ray machines. The method penetrates an object and a recording medium with radiation. Darker areas on the recording medium indicate more radiation passed through that area of the object, indicating cracks, voids, or density variation. X-rays are typically used for thinner materials; gamma rays for thicker. Film or computerized sensors can be used as recording media. Radiographic testing requires significant equipment and expertise, as well as safety precautions to prevent overexposure to radiation.

Neutron radiographic testing uses a concentrated ray of neutrons to penetrate objects, rather than X- or gamma rays. A linear accelerator or betatron must be used to generate these neutron beams. Neutrons pass through metals, but not most organic materials. When combined with standard radiography, this provides a more detailed picture of the interior of objects. This technology is only used in laboratory settings.

Magnetic Particle Testing (MT)

Magnetic particle testing uses the motion of indicator particles to evidence internal discontinuities in ferromagnetic materials. The part being testing must be coated in dyed magnetic particles, either in dry powder or liquid suspension form. A magnet induces an electromagnetic field into the material being tested. The field causes the magnetic particles to move towards any discontinuities transverse to the direction of the magnetic field, providing a visual indication of flaws.

Magnetic particle testing is a broad discipline, and a variety of methods can be used to induce magnetic fields. Magnetic particle testing requires significant setup and cleanup, and cannot easily be used in the field.

Acoustic Emission Testing (AET)

Acoustic emission testing relies on a similar principle of ultrasonic testing—the transmission of acoustic waves through solid objects. Wave propagation and measurement are accomplished by different means, however. Waves are induced via a sharp application of force to an object, such as the strike of a hammer or other mechanical load. Temperature and pressure changes can also induce appropriate waves.

Rather than listening for changes in wave characteristics and mapping from these, acoustic emission testing detects the physical motion of the medium itself. Changes or incongruities in the object’s material, such as a void, can be detected by differences in the movements detected by separate sensors. While effective for plastics and other materials, acoustic emission testing is less common and more equipment-intensive than other NDT methods. This technology is most often found in laboratory settings.

Thermal/Infrared Testing (IRT)

Thermal testing uses captured infrared radiation emitted from an object to provide an image of the object’s surface. Thermal imaging can indicate corrosion, voids, foreign objects, or delamination. Areas being scanned must be uncovered in order to provide the infrared camera with a direct line-of-sight. While thermal testing can be effective, the defects it detects can also be picked up by other methods that require far less extensive setup.

Vibration Analysis (VA)

Vibrations analysis excels at testing the integrity of rotating parts, including turbines, gears, shafts, and bearings. Three types of vibrations analysis are commonly used: accelerometers, velocity sensors, and eddy current displacement sensors.

Accelerometers are most effective for high-speed applications, as they are sensitive to high frequencies. Velocity sensors use a magnet to generate an electric field from the rotating part, allowing effective measurement of parts moving at slow or moderate speeds.

Eddy current displacement sensors measure the physical motion of the rotating part on unwanted horizontal or vertical axes. They can detect changes in clearance or shaft motion, indicating the need for repairs.

Liquid Penetrant Testing (PT)

Liquid penetrant testing provides visual indication of cracks or other defects that connect to the surface of materials. Liquid penetrant is primarily useful for non-porous materials, as porous materials obscure evidence of defects. This testing method coats or soaks materials in an indicator fluid. This fluid flows into openings in the material’s surface. When the liquid remaining on the surface is removed, the liquid returns from the cracks. Anywhere liquid resurfaces reveals a defect; the more liquid, the larger the defect.

Without a channel connecting a flaw to the surface, the liquid cannot enter it. So, other methods must be used to detect enclosed voids or honeycombing. The surface of the material must also be clean, as oils and other residues can’t interfere with the liquid’s ability to enter cracks. Additionally, liquid penetrant requires significant equipment, setup, and cleanup to handle the liquid itself. While this technique can be used effectively, it is often slower and more cumbersome than other NDT methods.

Leak Testing (LT)

Leak testing is a category of nondestructive testing, referring to several methods for determining the presence of leaks in sealed vessels. There are four common methods for detecting gas leaks, though some are similar. Pressure change testing either pressurizes or creates a vacuum in a sealed vessel. Loss of pressure or vacuum indicates a leak. Bubble testing also relies on a pressure indicator. Parts are pressurized, then immersed in fluid. The presence of bubbles indicates the location of a leak.

Halogen diode and mass spectrometer testing are similar, both using an identifier gas to detect the presence of a leak. Either halogen or helium (often mixed with air) is introduced into a pressurized vessel. A halogen diode detector or mass spectrometer located outside the pressurized area alerts technicians to the presence of halogen or helium, indicating a leak.

Some bubble tests can be performed onsite, with special equipment to create sealed areas on large and/or flat surfaces. However, bubble testing and other leak testing methods are time-consuming and require cumbersome equipment and setup. They are best performed in laboratory settings.

Comparing Nondestructive Testing Methods

Comparing different types of NDT can be difficult; each is unique and designed for its purpose. This also means that depending on the application, one certain type of NDT is likely to be required or preferred. Still, when the choice is unclear, it’s important to understand the relative merits of each NDT technique in order to make a correct equipment decision.

The chart below provides a general comparison of different types of NDT, what materials they are typically used for, and practical considerations like speed, set-up requirements, and hazards.

| Materials | Speed | Limits | Hazards | Set-up | |

| Ultrasonic | Steel, alloys, other metals, and composites | Fast | Rough, coarse, or overly thick materials | None | Fast |

| Eddy Current | Thin, conductive materials | Fast | Conductive materials only | None | Fast |

| Visual | All materials | Fast | Inability to detect small or hidden defects | None | Fast |

| Long-Range UT | Piping | Fast | Piping only | None | Significant |

| Magnetic Flux | Pipes, tubes, tank floors | Fast | Access | None | Moderate |

| Laser Testing | Metals, plastics, composites, piping | Fast | Access | Eye damage | Moderate |

| Radiography | Most materials | Fast | Large equipment and safety requirements | Radiation | Moderate |

| Magnetic Particle | Ferromagnetic materials | Fast | Ferromagnetic materials only | Particle and liquid containment | Slow |

| Acoustic Emission | Plastics, composites, metals | Moderate | Multiple sensors required | None | Moderate |

| Thermal Imaging | Metal, plastic, composites | Moderate | Access | None | Moderate |

| Vibration | Rotating objects | Moderate | Access | Proximity to rotating parts | Moderate |

| Liquid Penetrant | Non-porous materials | Slow | Access, liquid transportation | Liquid containment | Slow |

| Leak Testing | Sealed Vessels | Slow | Pressure chamber required | Pressure or vacuum | Slow |

Choosing the Right NDT for Your Application

In many cases, the right NDT method for a specific application is the one required by law. If no applicable laws specify a test method, guidance may still be found by reviewing the best practices published by international standards organizations. Similarly, the manufacturer of the part in question may also publish NDT standards and best practices for their part. If none of the above provides an answer, consult with a Level III NDT technician, who can recommend the best next steps to take. Generally speaking, fieldwork on metals and composites can likely be accomplished using either or both ultrasonic and eddy current testing equipment.

Not all NDT equipment is created equal. Some instruments are intended for laboratory work; others for rugged work in the field. Choosing the right NDT manufacturer is as important as finding the right method. Manufacturers can not only provide equipment, but also training, support, and advice. Those with deep industry experience have the institutional knowledge and experience needed to handle new or tricky inspection issues. Partnering with a trusted NDT manufacturer can provide not only effective NDT equipment, but also invaluable peace of mind.

Zetec has been a leading provider of NDT solutions for decades. To learn more about our ultrasonic and eddy current NDT equipment, contact us today!