Zetec Introduces FlexTrack Scanner Optimized for Aerospace Inspections

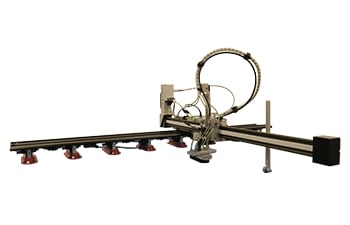

Zetec Inc. has introduced the FlexTrack automated X-Y scanner for nondestructive ultrasonic testing (UT) applications of materials and structures used predominantly in aerospace, both in production and maintenance environments.

FlexTrack is a versatile scanner that features a 24-inch motorized actuator arm moving on a flexible 54-inch track that uses suction cups to mount to virtually any surface. The actuator arm and track allow for automated raster scanning in both directions, and parallel or perpendicular probe orientation for exceptional coverage.

FlexTrack is available with one or two pieces of track, which can be connected and re-connected while scanning is under way. This gives technicians the ability to construct a virtually infinite scanning path by alternating the installation of pieces of track.

The actuator arm has a total length of 40.9 inches and can be removed from the track displacement module for easy transportation, storage, and installation.

Each piece of track features eight non-marring polyurethane suction cups, each with an independent Venturi system that optimizes the vacuum level so if one or more cups does not have complete seal, the remaining cups can produce a strong, secure mount that can support the weight of scanner.

“FlexTrack is designed specifically to meet the ultrasonic inspection needs of aerospace NDT applications, where large surface areas, a variety of materials, and complex geometries are common,” said Dominic Giguère, UT Product Manager. “It enhances the technician’s ability to deliver fast, accurate inspection results and improve productivity and safety.”